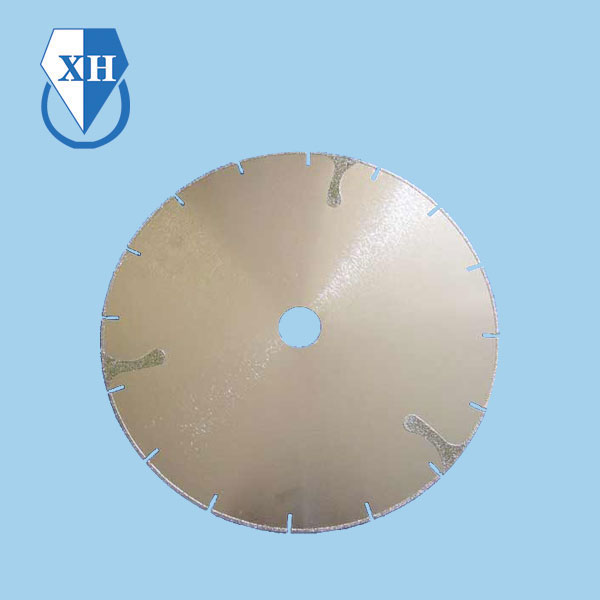

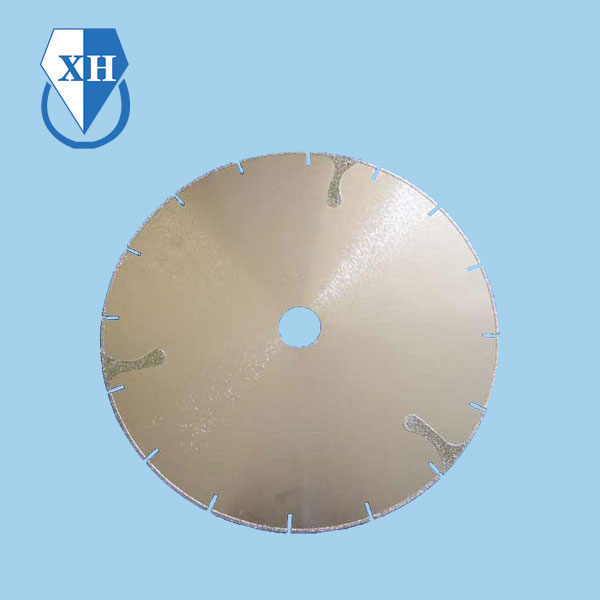

Composite Diamond Coating

Due to a series of excellent physical and chemical properties, such as high hardness, high strength, high wear resistance, and a low linear expansion coefficient, Composite Diamond Coating has been widely used in the field of grinding. However, at room temperature and atmospheric pressure, diamond i......

Send Inquiry

Product Description

Due to a series of excellent physical and chemical properties, such as high hardness, high strength, high wear resistance, and a low linear expansion coefficient, Composite Diamond Coating has been widely used in the field of grinding. However, at room temperature and atmospheric pressure, diamond is metastable, its heat resistance is not high, and there are some surface defects. In addition, due to the mechanical inlay between the diamond grains and the bond in the abrasive tools, the diamond grains are easy to fall off under the action of grinding force, which greatly reduces the service life of the abrasive tools.

Coating a layer of metal on the surface of diamond can give diamond many new characteristics: improving the strength of diamond, the interface bonding ability between diamond and matrix, oxygen barrier protection, reducing the degree of thermal damage to diamond, improving the physical and chemical properties of the interface between diamond and matrix, and improving the wear resistance and cutting ability of diamond tools. The metal to be plated is generally nickel, copper, silver, or alloy.

Assume full accountability to meet all requirements of our purchasers; realize continual advancements by selling the advancement of our customers; grow to be the final permanent cooperative partner of consumers; and maximize the interests of clients for IOS Certificate China Manufactured Titanium Coating Diamond CBN Powder/Nickel-Coated Synthetic Diamond, We welcome prospects, small business associations, and buddies from all parts of the globe to get in touch with us and search for cooperation for mutual positive aspects.